WT METERING PUMPS

The WT pump is the complete advanced solution for the control and dosing of biocide and inhibitor, which are essential for water treatment and disinfection, preventing thegrowth ofbacteria and algae inside evaporative towers. The WT also integrates the dosing function of the corrosion and scale inhibitor, ensuring continuous protection of metal surfaces and piping. Biocide and inhibitor dosing are managed in proportional mode on make-up water (either continuous or one-shot), timer or in proportion to discharge time. Through the Lockout feature ensures maximum efficiency in managing the chemical, while the Safety Timer on the discharge solenoid valve ensures that the system is always safe.

Remote management via ERMES/App MYEMEC ensures maximum flexibility and optimization in plant management.

Features

- Large LCD display with backlighting adaptive to device operation

- “Encoder” knob for controlling the instrument

- Box PC+ABS

- Flow control input

- Conductivity reading

– 0/3 mS – 0/30 mS (ECDINDPT)

– 0/10 mS (ECDSINDPT)

– 0/10 mS (ECDCCPT) - Temperature reading: 0 to 100°C

- Independent dosing of biocide and inhibitor

- Multiple dosing modes: proportional in ppm, daily/weekly timer

- Lockout Functionality

- Safety timer

- Alarms: level, no flow

- Digital inputs that can be set N.O. or N.C.

- Delayed start of dosing

- Permanent data storage with system log that can be viewed on display

- Bluetooth LE / WiFi 2.4Ghz connection for APP and Remote Control

- Firmware upgradeable (via OTA)

- Installation Class II (IEC / EN 61010-1)

- Pollution level 2 (IEC / EN 61010-1 and IEC 60664-1)

- Protection IP 65 (IEC / EN 60529)

- Manual or automatic purging

- Built-in MODBUS

- Vertical mounting

WT peristaltic (stepper)

Dual stepper technology motor associated with two long-life, low-permeabilityperistaltic tubes ideal in contexts of maximum safetyand precision dosing of biocide and inhibitor. Inverter function enables advanced chemical management in total operator safety. Scheduled maintenance functionality minimizes plant downtime. Automatic water discharge is managed according to the detected conductivity value, preventing accumulation of dissolved salts and ensuring optimal chemical balance in the cooling water circuit.

Engine and accessories

- 2 stepper motors continuously adjustable between 1 and 25 rpm

- Long-lasting peristaltic tubes (TPV)

Power supply

100 to 240 VAC

Performance

WT diaphragm (solenoid)

The diaphragm version is anadvanced solutionfor an extremely wide set of chemical dosing applications in evaporative towers due to its large range of flow rate/pressure. It is equipped with motion diaphragm mentation by solenoid with hydraulic parts made of PVDF with high chemical resistance. Built-in functions include manual or automatic purging, stand-by, delayed dosing start.

Engine and accessories

- Dual 45-pulse/min continuously adjustable magnet (1% – 100%)

- Valves with double ball

- Standard PVDF hydraulic parts

Power supply

115 VAC

230 VAC

Performance

Inputs

Conductivity probe, Input water meter, Level 1 and 2, Flow sensor, Standby

Outputs

Alarm (free contact relay), MODBUS RTU port, Pump 1 and 2, Bleed (water discharge)

METERING PUMPS VELON

VELON is the latest generation of compact peristaltic metering pump equipped with a high-precision electronically controlled multi-function stepper motor that ensures constant and regular chemical dosing, even under demanding working conditions and load variations. Designed to offer a complete and user-friendly solution in all those installation contexts that require precise, reliable, quiet and safe operation.

Thanks to stepper technology, it is possible to vary the rotation speed and thus modulate dosing in real time, in a range from 1% to 100%, thus finding perfect application environments where a wide range of dosing from 18 cc/h to 12 l/h at 2 bar is needed.

Capable of performing automatic chemical control and dosing according to the detected parameters, dynamically adapting to the needs of the plant. Through a wide set of dosing modes, it is capable of adapting to a wide variety of plant operational needs.

Maintenance activity counters make it possible to pre-schedule tube replacements according to wear and tear, while the facilitated tube change system makes operation quick and totally safe.

The wide range of variants (MF, PO, CL, PM) offers maximum versatility and ease of use in a wide variety of contexts, while multi-channel connectivity makes VELON an adoptable solution in any working environment. Where remote intervention is required, VELON’s full functionality can be accessed and managed via the ERMES portal or through the MyEmec app.

VELON MF

Multifunctional, with advanced interface, it is the complete solution for controlled dosing of chemicals, with a focus on integration with monitoring systems.

Ideal for:

- Installations where comprehensive and customizable dose management is needed.

- Contexts where reliability, simplicity and modernity must coexist.

FEATURES

Description

Multifunctional pump with extensive dosing modes and digital management even remotely.

Interface / Control

RGB backlit LCD display, encoder, remote management via app/web

Working modes

Constant, CC/Pulse, PPM, %, MLQ, Batch, Volt, mA, Pulse, Weekly Program, Ext Constant

Maintenance

Scheduled maintenance using activity counters.

Inputs

MODBUS RTU, Multi-function, Level

Outputs

Alarm (optional)

Connectivity

Wi-Fi & Bluetooth

Update Firmware

OTA

VELON PO

Proportional control with pH and Redox potential measurement, recommended for those seeking active and intelligent dosing management, connected directly to measured values in the plant.

Ideal for:

- Pool facilities.

- Complex systems requiring remote control and high reliability.

- Intelligent management based on process parameters.

FEATURES

Description

Versatile pump with proportional control and remote control.

Interface / Control

Backlit LCD display, encoder, remote management via app/web

Working modes

Proportional, Autodosing

Maintenance

Scheduled maintenance using activity counters.

Inputs

MODBUS RTU, Standby, Level, Serial Probe

Outputs

Alarm (optional)

Connectivity

Wi-Fi & Bluetooth

Update Firmware

OTA

VELON CL

Simple and reliable for standard applications, recommended for those seeking a compact, user-friendly system.

Ideal for:

- Daily and routine applications without the need for digital integrations.

- Quick and intuitive installations, even by unskilled operators.

- Contexts where ease of use matters.

FEATURES

Description

Essential, practical pump for constant dosing with manual adjustment by potentiometer.

Interface / Control

Front potentiometer, LED, ON/OFF button

Working mode

Costant

Maintenance

Scheduled maintenance using activity counters.

Inputs

Level

Outputs

Alarm (optional)

VELON PM

Maximum integration with automated systems, suitable for industrial plants, automation systems and applications where digital communication (MODBUS) is indispensable.

Ideal for:

- Industrial systems and complex plants with driven automation requirements.

- Complex systems requiring remote control and high reliability.

- Intelligent management based on process parameters.

FEATURES

Description

Pump with MODBUS RTU integration, ideal for automated systems.

Interface / Control

MODBUS RTU, LED, ON/OFF button

Working mode

External Control

Maintenance

Scheduled maintenance using activity counters.

Inputs

MODBUS RTU, Level

Outputs

Alarm (optional)

FEATURES COMMON TO THE ENTIRE SERIES

Microprocessor

Latest generation high performance

Pressure (bar – psi)

2 (29)

Protection

IP65

Power supply

100-240VAC, 12VDC, 24VDC

Range Flow rate

(l/h – gal/h)

(Ø1.6×1.6)

0.018 – 1.8 l/h

0.0047 – 0.47 gal/h

Range Flow rate

(l/h – gal/h)

(Ø4.8×1.6)

0.12 – 12 l/h

0.0317 – 3.17 gal/h

Operating Temperature

10 – 45 °C

55 – 113 °F

Range Flow rate

(l/h – gal/h)

(Ø1.6×1.6)

0.018 – 1.8 l/h

0.0047 – 0.47 gal/h

Range Flow rate

(l/h – gal/h)

(Ø4.8×1.6)

0.12 – 12 l/h

0.0317 – 3.17 gal/h

Class Installation

II

Materials Construction

PC/ABS, PVDF, POM, TPV

Remote control

Web (ERMES) and App (MyEmec)

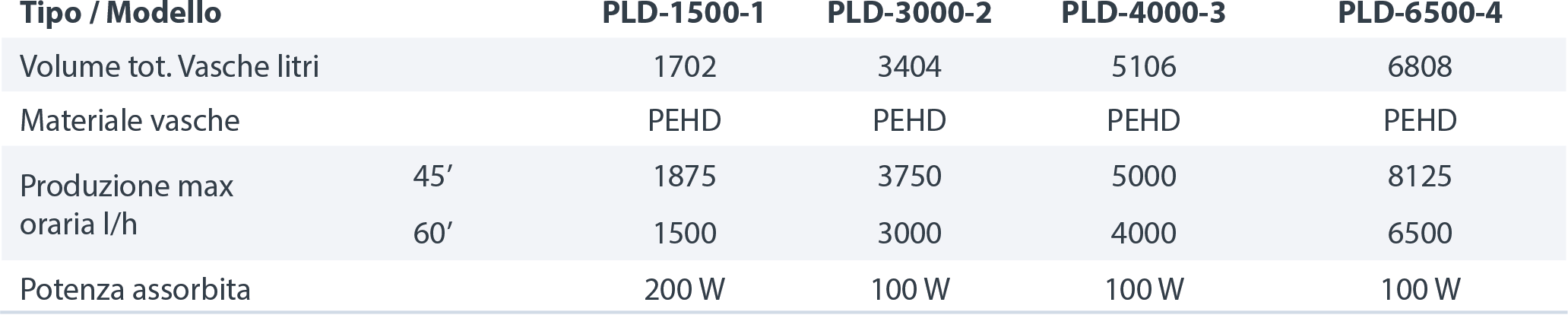

POLYPREPARATOR TetraMix

COMPACT AND AUTOMATIC EFFICIENCY

The TetraMix (EMEC polypreparator) is a modular and expandable, fully automatic system designed for the continuous preparation of polyelectrolyte solutions from dry polymers. Indispensable in civil and industrial wastewater treatment plants, it ensures high performance in sedimentation, clariflocculation and sludge dewatering processes through the use of advanced technologies (such as brushless motors), and high-quality construction materials (PEHD, PPH, PVC, AISI 304).

Applications

- Civil and industrial sewage treatment plants

- Sludge and effluent treatment

- Food and beverage sector

- Chemical and pharmaceutical industry

- Processes with floaters, decanters, filter presses

The TetraMix model is equipped with PEHD tanks and a PPH powder feeder with hopper, connected to an expandable and hermetically resealable container that provides maximum operator safety, inside of which is housed a plastic-coated auger. The four-blade propeller agitator, driven by a brushless motor, ensures precise speed regulation and a significant reduction in energy consumption. The system is complemented by a hydraulic circuit with meter, solenoid block valves, and control valves. The system is fully automated with radar level probes and integrated safety devices.

Benefits

- Automatic preparation: reduced manual labor and errors, ready-to-use solution

- Maximum effectiveness: Hydration and activation of polyelectrolyte (powder or emulsion)

- Maximum efficiency: solution optimization and polymer activation

- Flexibility: modular configurations for different needs

- Savings: waste reduction, reduced energy consumption and simplified maintenance

- High performance: continuous process and consistent quality

- Ripening time: powder 30-60 min

- Outlet connections: 2″

Process

1 I MIXING

Dosage and initial homogenization of reagents

3 I STORAGE.

Controlled storage pending use

2 I MATURATION

Reaction and stabilization of the mixture

4 I PRELIMINATION.

Precise and smooth delivery of the solution

Features

- PPH powder dispenser

- Adjustment by brushless motor with electronic variation from HMI

- 35-liter loading hopper with vibrator

- Radar dust level control (minimum level)

- Powder adjustment concentration 0.05 to 0.5 percent

- Preparation water supply device consisting of.

- Ultrasonic electronic flow meter (4-20 mA)

- Radar level controller (solution)

- Agitator Mixer

- L1000 three-phase brushless motorisation – 400 W

- 4-blade propeller Ø 400 mm

- Electrical command and control panel

- Utility Management via 7″ Touch Screen HMI

- Ethernet TCP/IP communication

- ABS IP65 housing to protect electronic components

Main alarms

- Automatic preparation: reduced manual labor and errors, ready-to-use solution

- Maximum effectiveness: Hydration and activation of polyelectrolyte (powder or emulsion)

- Maximum efficiency: solution optimization and polymer activation

- Flexibility: modular configurations for different needs

- Savings: waste reduction, reduced energy consumption and simplified maintenance

- High performance: continuous process and consistent quality

- Ripening time: powder 30-60 min

- Outlet connections: 2″

Expandable modular system

The system provides an independent master tank, expandable with additional modules to adapt to different dosing and storage needs. Assembly, using rectangular flanges with gaskets and M8 screws, ensures solidity and rapid installation.

Tub measures mm : 1400x1400xh1200

MDS NH2Cl is a compact and automatic system designed for the production of Monochloramine

in aqueous solution for water treatment, within the scope of the intended uses

in these instructions.

MDS NH2Cl simultaneously doses two chemicals Ammonia (at known %), Hypochlorite of

Sodium (at known %), into water inside the reactor. Generation is monitored by the HMI and can

be adjusted by a flow meter with the main water flow.

The system includes three protections:

- A protection for the NH3 metering pump

- A protection for the NaClO dosing pump.

- A protection from the minimum flow rate reading of the dilution water meter

NH2Cl generation occurs inside a reactor with external water flow to protect the reactor. Inside the reactor, the two reactants react with dilution water at a concentration of approx. 2 g/l (2000 ppm).

NIMBUS by emec

MORE EFFICIENCY, LESS WASTE,

FULL CONTROL.

INTUITIVE AND CUSTOMIZABLE DASHBOARD

INTERACTIVE MAP WITH REAL-TIME MONITORING OF SYSTEMS AND DEVICES

BUILT-IN GEOLOCATION FOR ALL YOUR INSTALLATIONS AND DEVICES

REMOTE SETUP AND CONTROL, ANYTIME, ANYWHERE

REMOTE SETUP AND CONTROL, ANYTIME, ANYWHERE

GUIDED DEVICE REGISTRATION

REMOTE SETUP AND CONTROL, ANYTIME, ANYWHERE

REMOTE SETUP AND CONTROL, ANYTIME, ANYWHERE

GUIDED DEVICE REGISTRATION

REMOTE SETUP AND CONTROL, ANYTIME, ANYWHERE

REMOTE SETUP AND CONTROL, ANYTIME, ANYWHERE