POLY-PREPARATORTetraMix

COMPACT AND AUTOMATIC EFFICIENCY

The TetraMix (EMEC polypreparator) is a modular and expandable, fully automatic system designed for the continuous preparation of polyelectrolyte solutions from dry polymers. Indispensable in civil and industrial wastewater treatment plants, it ensures high performance in sedimentation, clariflocculation and sludge dewatering processes through the use of advanced technologies (such as brushless motors), and high-quality construction materials (PEHD, PPH, PVC, AISI 304).

Applications

- Civil and industrial sewage treatment plants

- Sludge and effluent treatment

- Food and beverage sector

- Chemical and pharmaceutical industry

- Processes with floaters, decanters, filter presses

The TetraMix model is equipped with PEHD tanks and a PPH powder feeder with hopper, connected to an expandable and hermetically resealable container that provides maximum operator safety, inside of which is housed a plastic-coated auger. The four-blade propeller agitator, driven by a brushless motor, ensures precise speed regulation and a significant reduction in energy consumption. The system is complemented by a hydraulic circuit with meter, solenoid block valves, and control valves. The system is fully automated with radar level probes and integrated safety devices.

Benefits

- Automatic preparation: reduced manual labor and errors, ready-to-use solution

- Maximum effectiveness: Hydration and activation of polyelectrolyte (powder or emulsion)

- Maximum efficiency: solution optimization and polymer activation

- Flexibility: modular configurations for different needs

- Savings: waste reduction, reduced energy consumption and simplified maintenance

- High performance: continuous process and consistent quality

- Ripening time: powder 30-60 min

- Outlet connections: 2″

Process

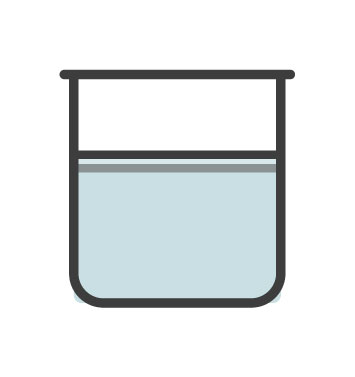

1 I MIXING

Dosage and initial homogenization of reagents

3 I STOCKING

Controlled storage pending use

2 I MATURATION

Reaction and stabilization of the mixture

4 I WITHDRAWAL

Precise and smooth delivery of the solution

Features

- PPH powder dispenser

- Adjustment by brushless motor with electronic variation from HMI

- 35-liter loading hopper with vibrator

- Radar dust level control (minimum level)

- Powder adjustment concentration 0.05 to 0.5 percent

- Preparation water supply device consisting of.

- Ultrasonic electronic flow meter (4-20 mA)

- Radar level controller (solution)

- Agitator Mixer

- L1000 three-phase brushless motorisation – 400 W

- 4-blade propeller Ø 400 mm

- Electrical command and control panel

- Utility Management via 7″ Touch Screen HMI

- Ethernet TCP/IP communication

- ABS IP65 housing to protect electronic components

Main alarms

- Automatic preparation: reduced manual labor and errors, ready-to-use solution

- Maximum effectiveness: Hydration and activation of polyelectrolyte (powder or emulsion)

- Maximum efficiency: solution optimization and polymer activation

- Flexibility: modular configurations for different needs

- Savings: waste reduction, reduced energy consumption and simplified maintenance

- High performance: continuous process and consistent quality

- Ripening time: powder 30-60 min

- Outlet connections: 2″

Expandable modular system

The system provides an independent master tank, expandable with additional modules to adapt to different dosing and storage needs. Assembly, using rectangular flanges with gaskets and M8 screws, ensures solidity and rapid installation.

Tub measures mm : 1400x1400xh1200